How to write a standard operating procedure (‘SOP’) - In 10 simple steps.

Need to know ‘how to write standard operating procedures (SOPs)’ to better communicate processes to your team and ensure they follow them? Want to know how to create a standard operating procedure to include in your manual? Interested to see how a professional manual writer does it? We tell all in this in-depth article.

The importance of SOPs.

Business operating manuals (aka ‘operations manuals’) must clearly communicate the best way to do everything in your business to ensure its quality, efficiency, profitability and success.

Operations manuals can serve other purposes – such as imposing rules; defining roles and relationships; providing reference; ensuring continuity; protecting against the loss of key persons; framing a business for sale or merger; codifying a franchise (in a franchise manual); ensuring compliance and detailing statutory policies etc. – but their most important function is to make sure your staff (or franchisees) do things right, so your organisation performs.

Thus, manuals should focus on ‘how to do things’ and set out everything you do in clear steps – i.e. by creating a ‘standard operating procedure’ (SOP) for every process.

If your manuals are full of ‘waffle’, ‘legalese’ and ‘prescription’, without clear step-by-step SOPs, they won’t help your staff do a better job nor do anything to improve your business.

Get in touch to see how Manual Writers can write better manuals and individual procedures for you, in simple and affordable ways. Here.

10 simple steps for excellent standard operating procedures:

Follow these 10 steps to write your own standard operating procedures (or simply ask us to do it all for you, here).

These steps apply equally in any sector - whether you’re in food, franchising or follicles - the process of writing a good SOP is the same!

Click on any image to enlarge.

1. Create a flowchart (or list) of all procedures.

You must identify all procedures in your business and how they interact, before writing up individual SOPs. Otherwise, you might miss important steps that are fundamental to your success (even if some seem minor).

Imagine you’re writing a standard operating procedure to change a car tyre and forget to mention removing the wheel from the car or jacking-up the car before that. Okay, these steps should be obvious, but your SOPs would be incomplete and nonsensical without them.

The simplest way to ensure you remember all steps is to create a simple flowchart.

Your flowchart doesn’t need to be formal or use the proper icons (‘action symbols’); Simply write out each operation in main steps and connect them in a flow with arrows, like this:

In the simple example above, each stage of fixing a car tyre is mapped out and connected.

By creating simple flowcharts like this, you can easily see which operations require their own standard operating procedure (SOP), which form part of another SOP, which could be improved with a better SOP and where a SOP would be advantageous but is currently missing.

E.g. in the above:

‘Repair tyre’ requires a SOP to inform technicians how best to repair punctures step-by-step, but ‘fill to correct PSI’ is just one of the final steps in that procedure.

If technicians don’t always jack-up cars in the right place (causing damage and complaints), this might be improved with a SOP for ‘jack up car at correct point’.

It might be worth creating a SOP for ‘choose tyre’ if that would help up-sell better (more profitable) tyres to customers.

Flowcharts (or lists) help you identify all the stages needed to provide your product or service with the greatest quality, efficiency and profitability – thus the standard operating procedures you need to write.

2. List every step in the procedure you’re working on.

Now you know the operations to create SOPs for and the main stages surrounding them, pick the first standard operating procedure you want to write.

It’s often simpler to write SOPs in the same order they happen in your operation, because you’ll find it easier to think things through logically, include everything necessary and link SOPs to the next process that way.

Start by ‘sketching out’ each step in the chosen process by simply listing them, so you don’t leave anything out. Thus, using the same example; ‘Replace tyre’ might turn into:

As you can see in the simple example above (noting that we aren’t mechanics!), listing the main steps in a procedure allows you to start thinking about the additional detail you need to spell out in the final SOP.

I.e. in the above example:

Step 5 would need to detail exactly how to properly clamp a wheel to the tyre-changer machine.

Step 17 requires provision of an external reference chart of the correct PSI for different tyres, vehicles and tyre positions.

Listing the main steps in each procedure thus gives you a good foundation from which you can write the first draft of a standard operating procedure.

We would advise you to do this for all the SOPs you want to write, before completing the next steps below.

That way your entire set of new operating procedures will move quicker together towards completion. (The danger of writing piecemeal is that you’ll get overinvolved in one process and run out of steam before completing others).

3. Sanity-check and test your process steps.

Now you have a list of the main steps in each procedure, it makes sense to check that they work in the real world before proceeding any further. By testing procedures ‘on the shop floor’ you might discover you’ve missed a step, got the order wrong or your staff know a better way of doing things.

To test a ‘sketched procedure’ (see point 2 of this article), do the following:

Read through your sketched procedure several times to ‘sanity check’ it (i.e. processes make sense in the order listed).

Hand it to an experienced colleague to review.

Test the procedure ‘on the shop floor’ using only your steps. Note results.

Talk to frontline staff. Get their feedback on your steps, clarity and improving the process.

Gather all testing results and feedback. Amend your procedure and steps as necessary.

Take a note of external resources (e.g. reference charts, forms, specifications, etc.) needed to support your procedure.

Consider what integrated resources (e.g. training, quick reference cards, posters etc.) are needed to help staff follow your new procedure.

(But note: When involving others in testing, don’t let their resistance to change interfere with your introduction of genuine improvements).

Testing also allows you to improve the processes you observe. Ask yourself:

How can we speed up this process?

How can we sell more or increase productivity in this process?

How can we improve quality and or customer service in this process?

How can we reduce waste in this process (mistakes, time, wasted materials, returns etc.)?

How can we increase the profitability of this process?

How can we improve this process to help other processes up or down the line?

How can we add a USP or differentiate ourselves from the competition in this process?

How can we improve skills, knowledge and or training in this process?

Do we need to improve machinery, resources or materials in this process?

Don’t create new standard operating procedures (SOPs) without testing them first.

If one procedure doesn’t work (or could be improved), your staff will lose faith in all the SOPs you introduce; efficiency (and so profitability) will suffer; and your manuals will no longer provide the single unquestionable source of instruction needed to drive your success.

4. Understand the audience for your SOP.

Now we have the basics of a decent standard operating procedure in place, we need to understand WHO we are creating that SOP for; so we can communicate with that audience in the best way (per their needs, function, level of experience, technical knowledge, literacy etc.).

For example:

A frontline worker may only need to know what to do (and how to do it) – in what order. So, they are more likely to benefit from simple step-by-step SOPs in plain English or graphics.

A qualified maintenance technician might expect SOPs to assume some pre-existing skill and to include more technical language, specification and external reference.

A salesperson may respond better to a positive informal tone than a formal prescriptive one.

A compliance officer is likely to be more comfortable with (and require) higher-level legal language, formality and detail.

A senior manager may respond well to internal jargon and need only a summary of each procedure but require higher-level insight into their management and impact.

You must write standard operating procedures in the style, tone, language, format and level of detail that is most easily understood by the staff using them.

E.g. You will unnecessarily confuse frontline workers by adding too much technical detail to a SOP, if they need only push button ‘A’ on a machine before button ‘B’. But avoiding technical language in a SOP to repair that same machine will equally confuse the qualified engineers sent to fix it.

If you don’t understand the audience for each SOP (so write ‘above’ or ‘below’ their requirements), you simply won’t communicate what you want to. Your new SOP could end up confusing more than it clarifies and annoy staff by being too convoluted or too condescending.

5. Consider how to present additional detail and reference.

By testing your sketched procedures and identifying the audience for each one, you should now understand the level of detail required in every SOP.

But you need to be careful. Presenting too much detail within a SOP might make it convoluted, confusing and difficult to follow.

E.g. in the below, the flow of a SOP is ruined by the inclusion of too much detail:

Consider how much detail you can move into external resources without diluting the authority of your SOP. (E.g. by referring out to appendices, supporting documents, online and intranet reference, charts, specification sheets, posters, quick reference guides, laminated cards, Apps etc.).

I.e. in this example, the same SOP is much clearer because detail is referenced out:

An additional benefit of referencing out your most changeable detail (e.g. prices, product and service specifications, suppliers, machinery specifications etc.) is that external reference documents can easily be updated without affecting the authority of your manual or rewriting any procedures.

6. Write a first formal-draft SOP.

Now you know what you’re writing and how to handle additional detail, it’s time to create the first formal draft of your standard operating procedure (SOP).

For now, keep this text based and don’t worry about design.

I.e.:

Write out numbered processes again with any amendments and improvements made using Steps 3-5 of this article.

Add the detail you want to include within your SOP.

Note (on your list of steps) the external resources referred out from your SOP.

Note where to add charts, forms, photos, graphics etc.

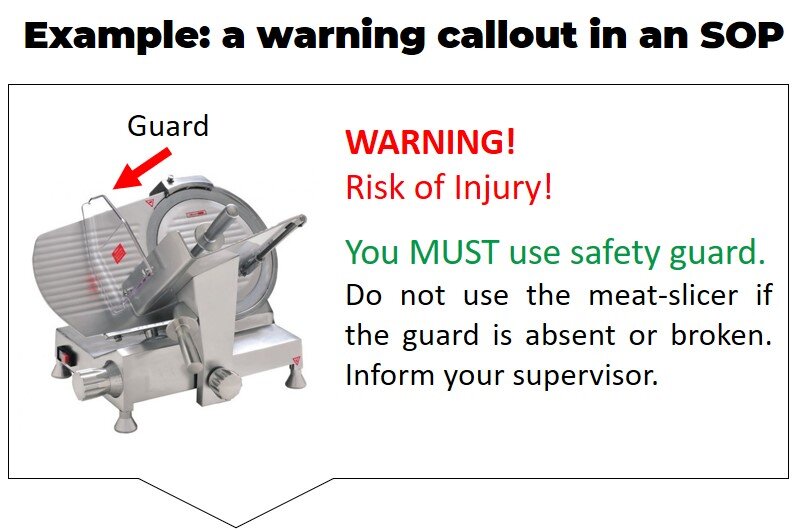

Note important information (such as danger warnings, operational tips, customer service touches, waste prevention, important rules, opportunities to upsell etc.) that you wish to highlight in the final version with callout boxes, icons, quotes, examples, different colours or formatting etc.

Doing this in a simple table will help you add clearer notes, so your first draft might look something like this:

7. Choose the best format.

Having written up the first formal draft, you must now consider how best to format and present it to the staff who will use it – so you communicate things effectively.

Bear in mind that frontline staff may prefer instruction in simple steps supported by photos and graphics for quick reference, whereas legal and management staff may prefer more detail and be comfortable with clearly formatted pages of text.

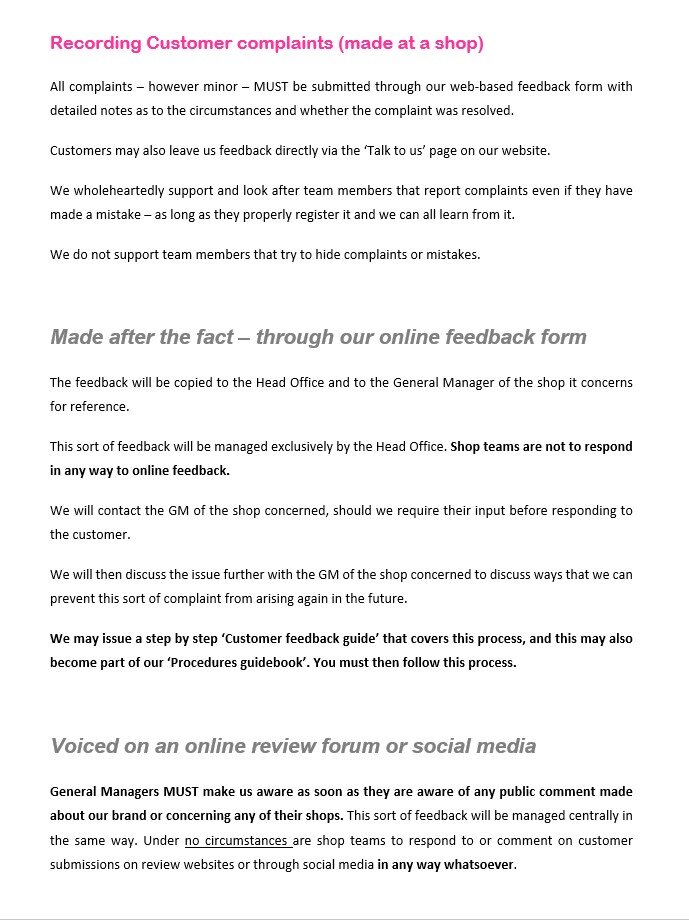

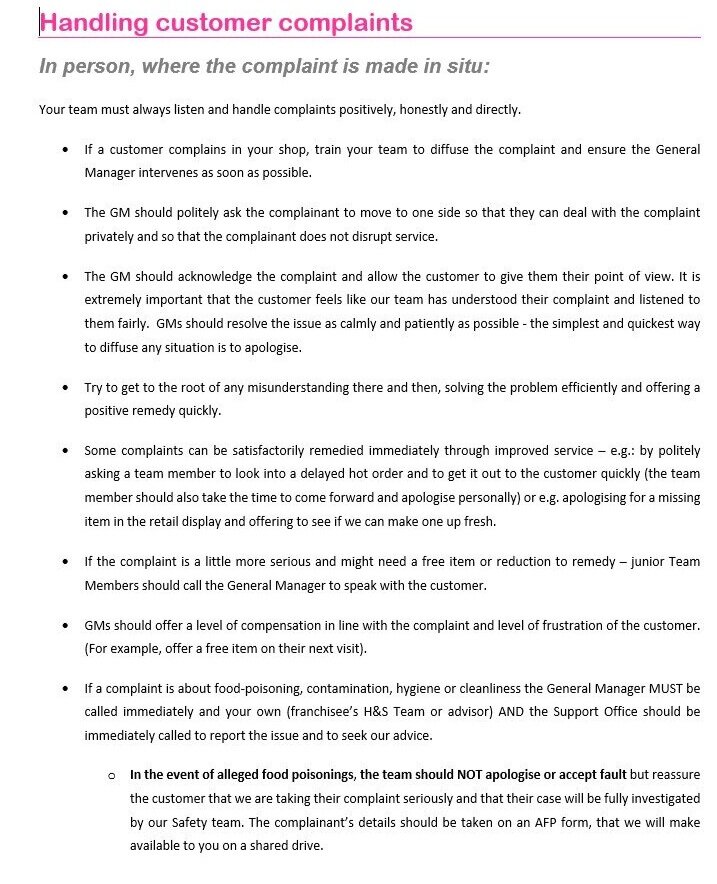

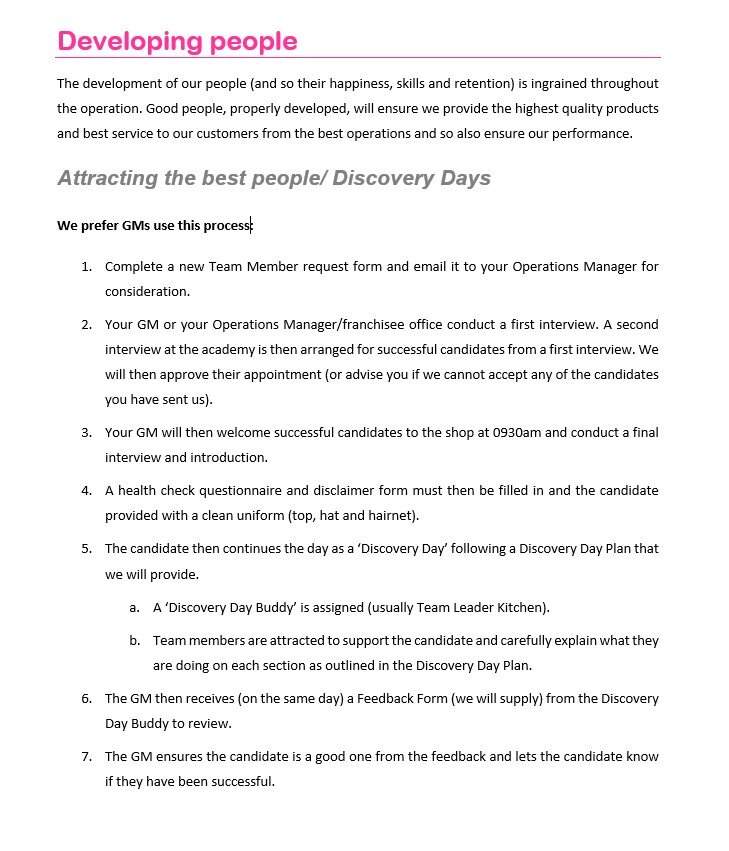

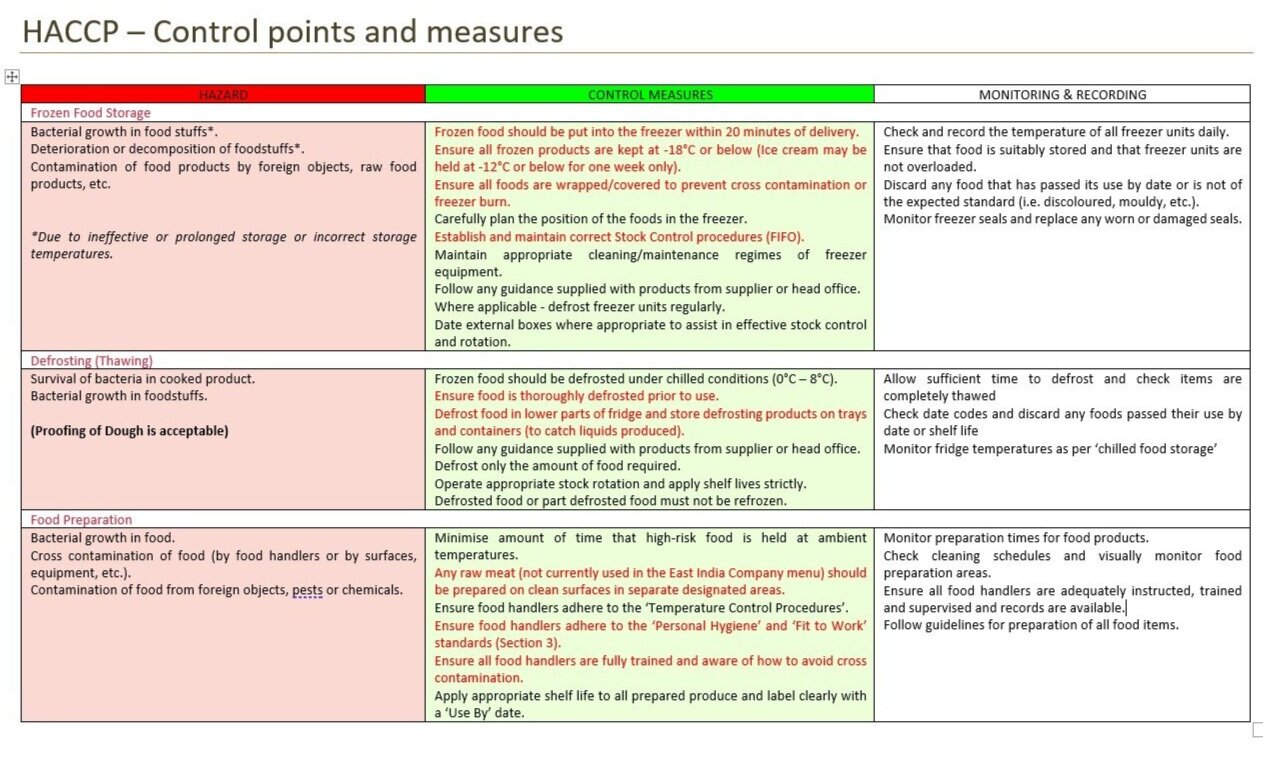

There are many SOP design formats to choose from, some include:

Neatly formatted narrative (step-by-step procedures are usually better than narrative).

Step-by-step bulleted or numbered lists (but try not to break steps across pages).

Tables.

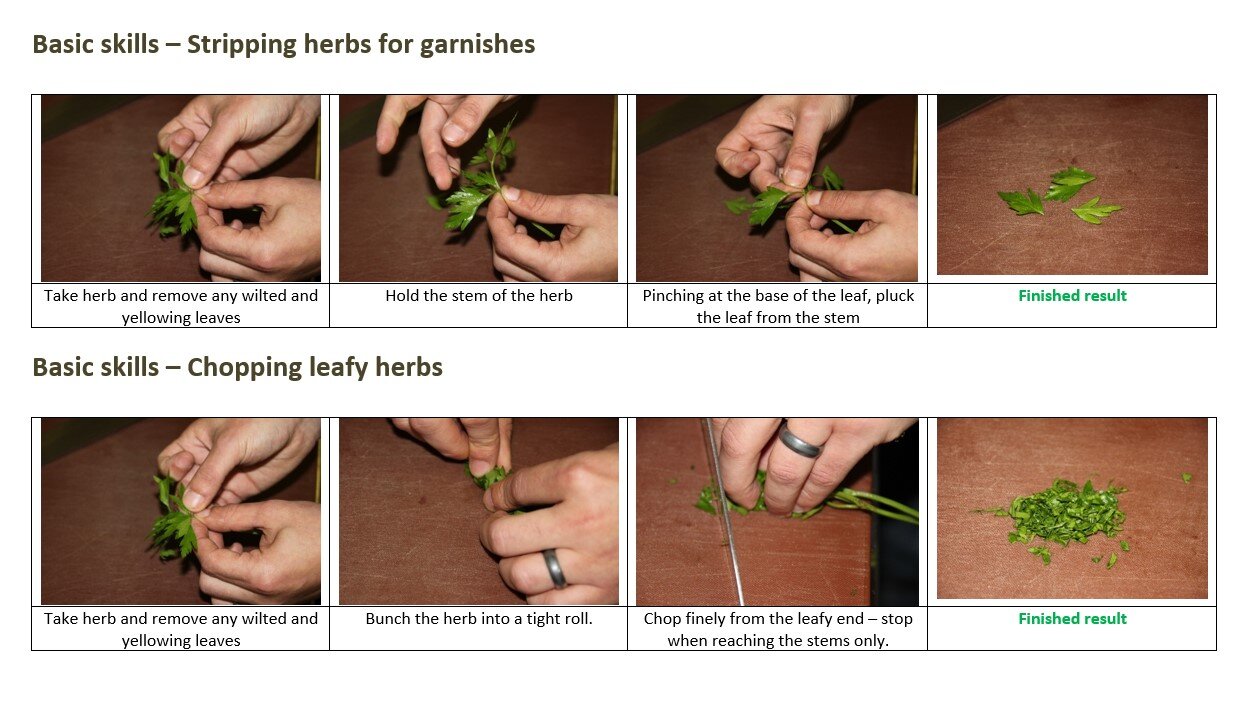

Step-by-step photos.

Step-by-step graphics.

Step-by-step comic strips (as created for a national chain).

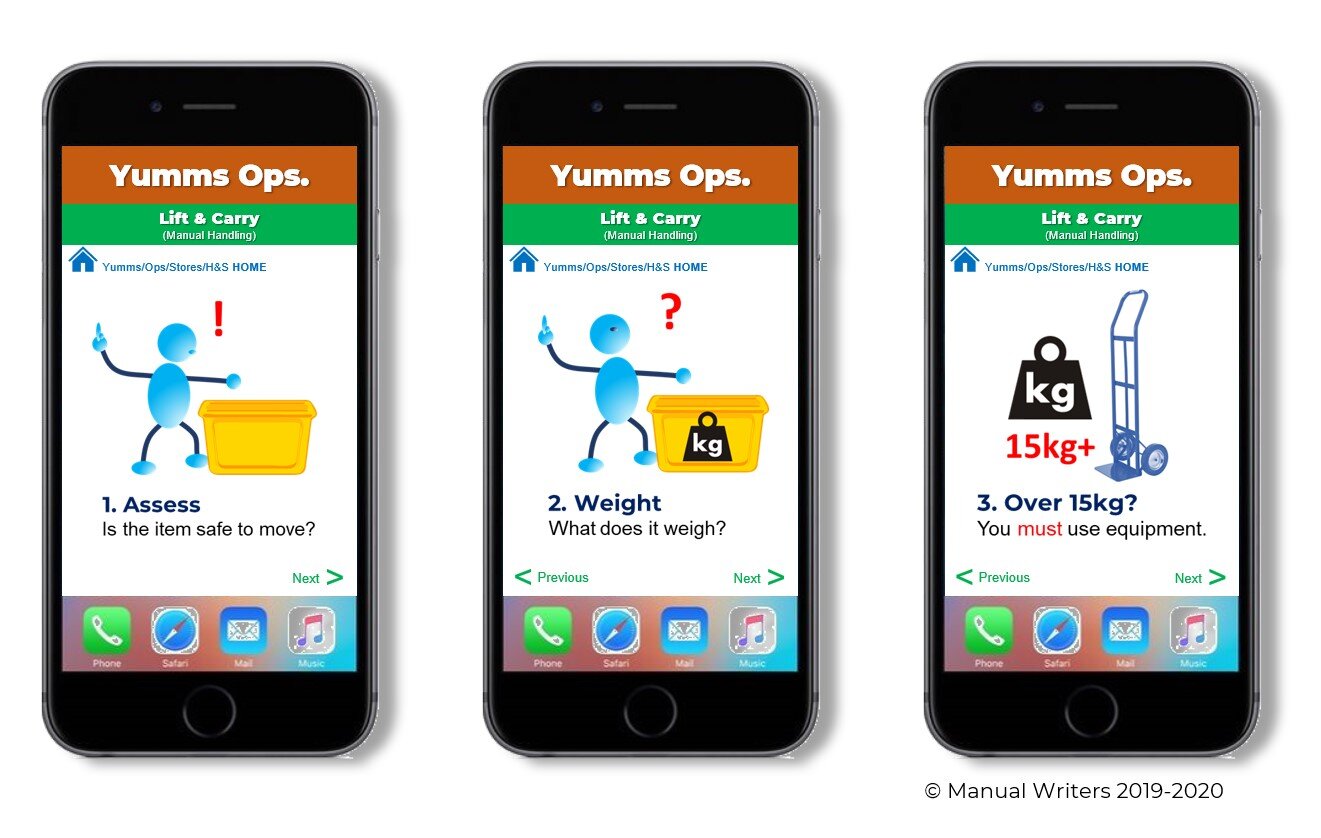

Step-by-step web pages or Apps.

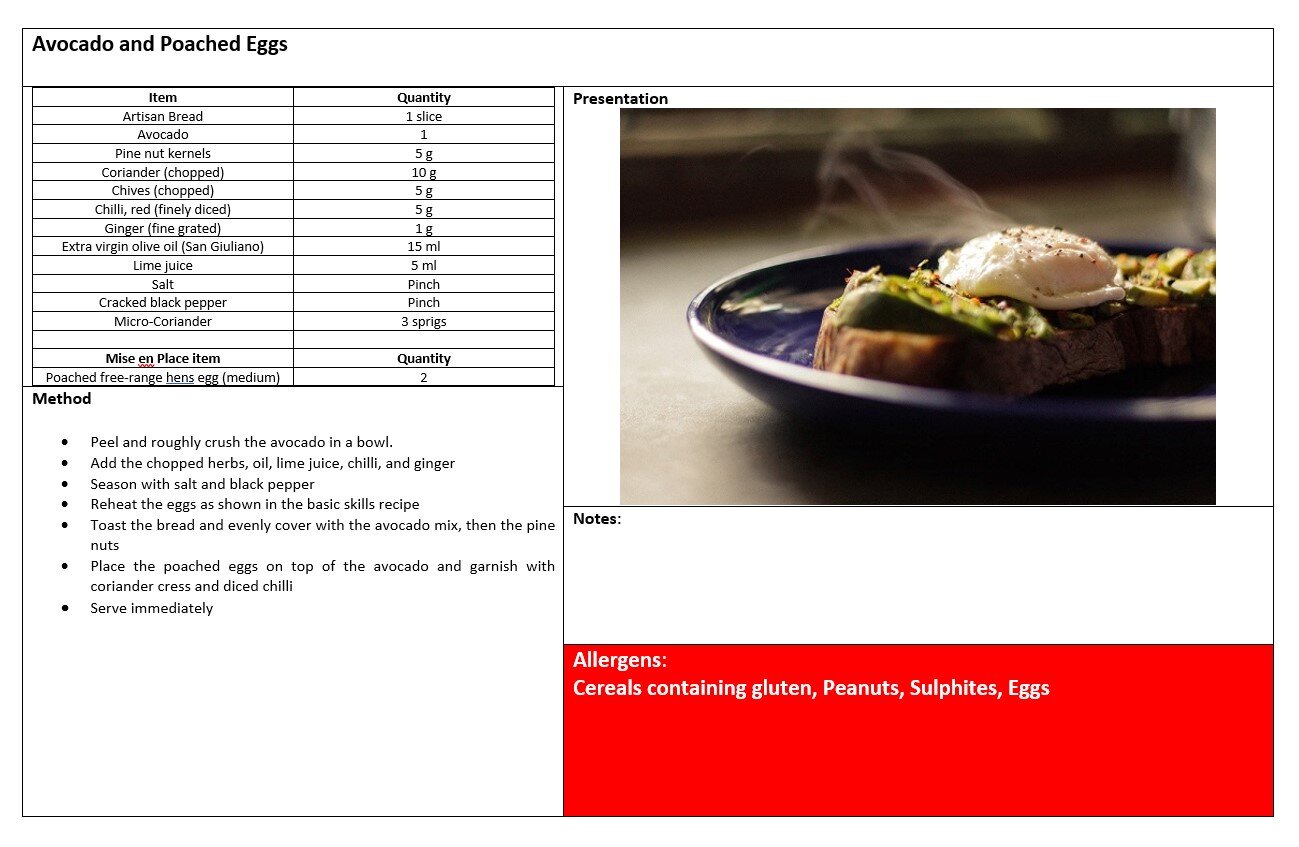

Quick reference cards (commonly used for recipes, at workstations or in manufacturing).

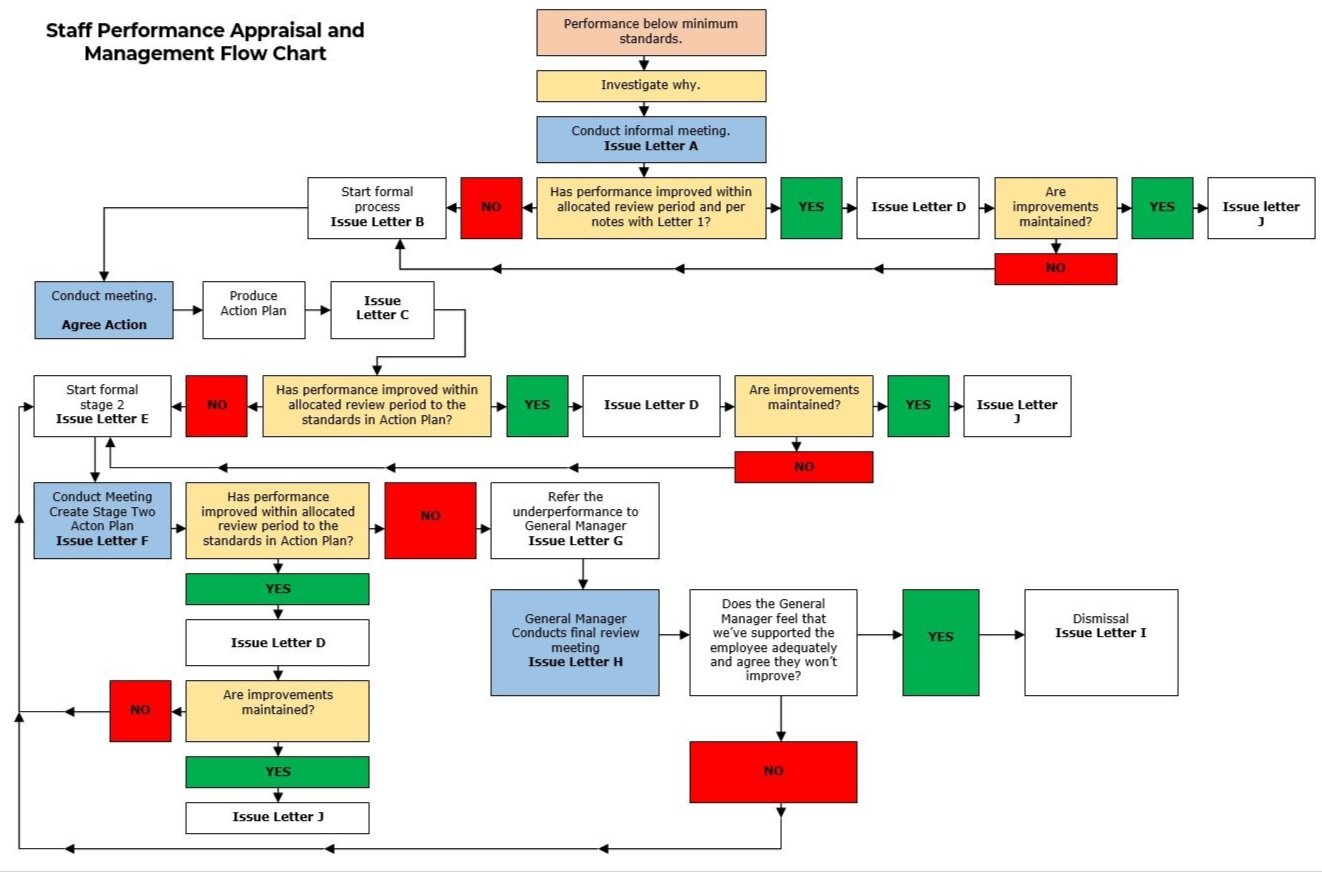

Flowcharts. (Use simple boxes connected by arrows; formal flowchart ‘action symbols’ can confuse readers, unless they are from a technical or academic background).

One-page graphics.

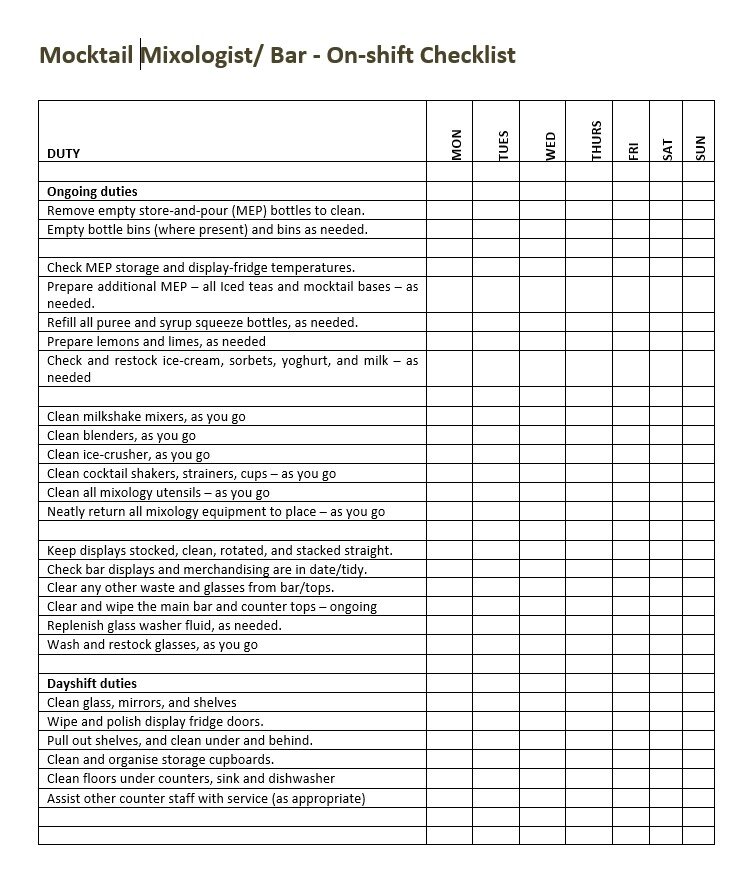

Checklists.

See examples of some of these below.

We’ve kept content in these examples within one sector (food) to make it easier to compare – but design formats are similar in all the sectors Manual Writers creates manuals and training for (automotive, catering, cleaning, building, development, distribution, entertainment, environment, financial, fashion, fast food, food retail, franchising, haulage, home improvement, holiday sector, hotels, manufacturing, online, professional services, pet care, property, restaurants, retail, services, social and not for profit, trades, utilities and many more.)

(Click any image to enlarge - hover when enlarged to see title)

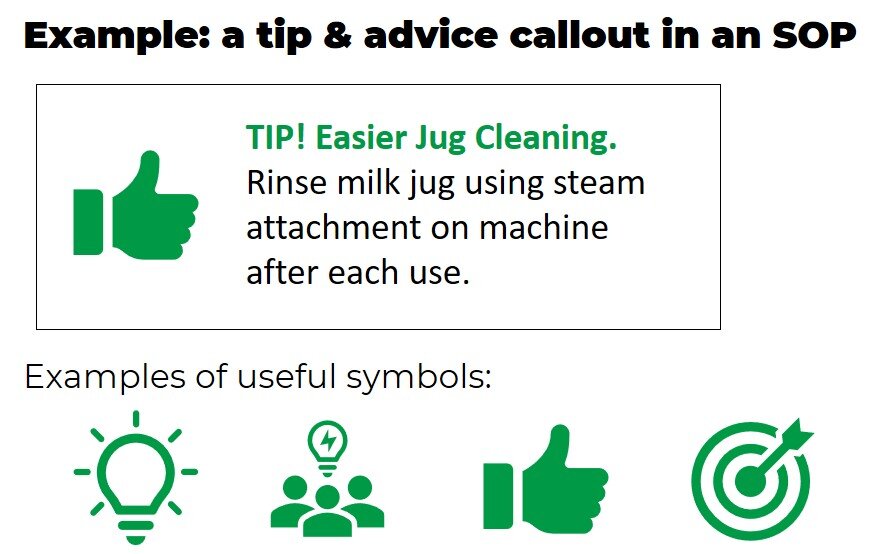

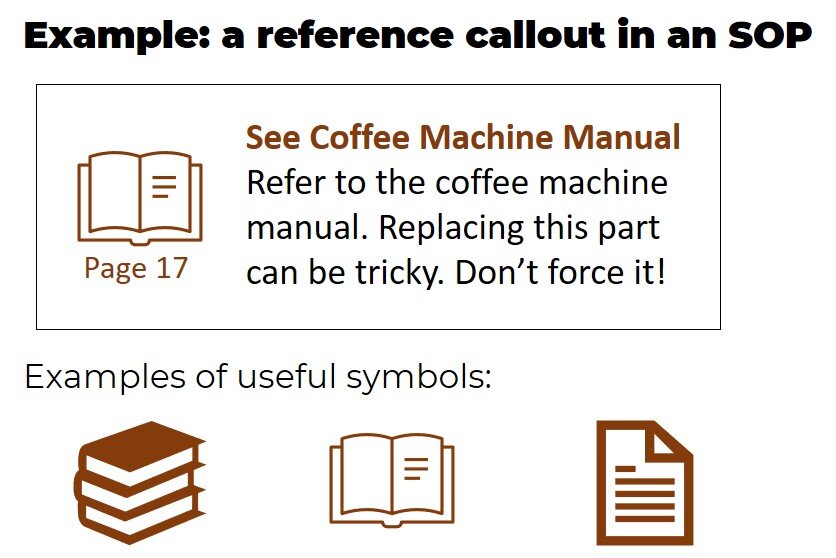

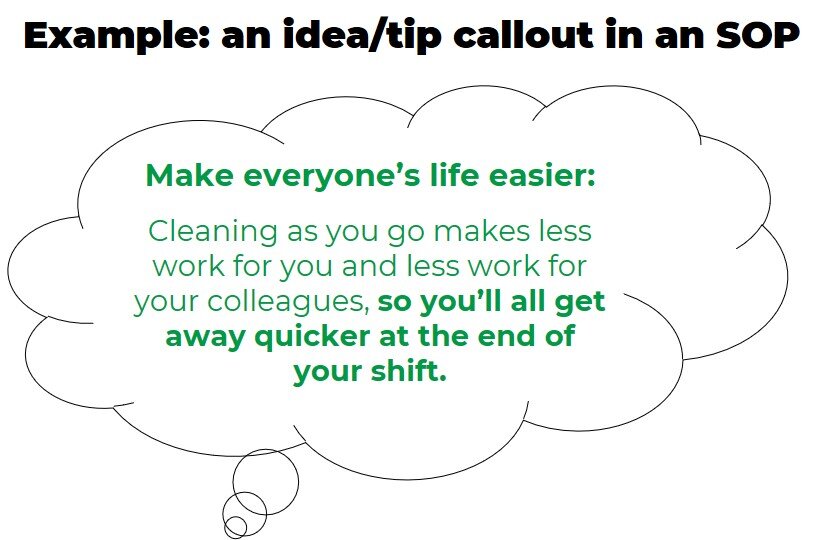

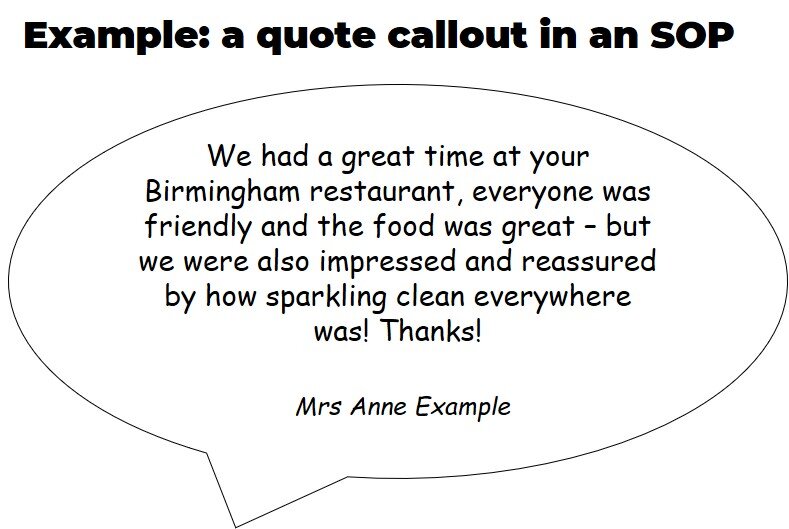

You can also include callout boxes, icons, boxed quotes, examples, different colours or formatting to highlight important messages or text within your SOP.

Again, see examples of some of these below (click to enlarge).

NB: STANDARDISE YOUR SOP FORMATS.

Your standard operating procedures (and the manual that collates them) will be confusing if you use too many different formats to communicate similar information.

E.g.

If a reader expects all frontline operations to be presented in step-by-step photos, they might easily ignore an important SOP presented as a page of text.

If you’re not consistent in the formats you use for one audience, it will be more difficult for them to find what they need. Try to keep all SOPs for the same audience or department within one design set.

If you use too many different colours, fonts and image styles within a single SOP, they will confuse the reader and distract from what you are trying to communicate.

It is better to create a single set of coherent and unchanging formats BEFORE you write SOPs. Then to pick an appropriate template from that set to ‘write into’, based on subject, department, function and audience. (This is also faster and cheaper than writing up SOPs and redesigning each one later).

8. Create photography and graphics.

Having written the text for your SOP into a standard format, you may wish to add photos and graphics to enhance and support it.

It is better to leave this until AFTER you’ve written your SOP because it’s likely you’ll want to change the content or number of images you use in the end. (You can still use draft images as reference or placeholders while writing, if needed).

Here are some tips for creating the best images in SOPs:

Photos:

If you can afford it, use a professional to photograph your most significant processes and provide them with an incredibly detailed brief before they start. Professional photos are properly lit and focused on the subject, so show more detail. Finished SOPs will also look better thus instilling confidence and higher brand values in your staff. (Amateur snapshots may suffice for less important images).

Photographs are often clearer than graphics when depicting real-life processes. They are more relatable and capture detail (irrespective of the intention of the photographer) that you may forget in a drawing. (If photos are reproduced in full colour and decent resolution).

Use close-ups. You may be tempted to use wider angle shots that show staff in correct uniform, properly decorated premises and branding (etc.) – but these can change (requiring updates to SOPs that could have been avoided). Close-ups are usually clearer anyway.

Include people in your photos (or their hands, faces, etc.) – if this doesn’t conflict with the above tip. Readers identify with and better understand images that include people.

Graphics:

Use a professional illustrator/designer for your most significant graphics.

Try to keep graphics within one style-set and use corporate colours.

Graphics are better than photos in depicting concepts.

Graphics may occasionally be better than photos when depicting processes, if the process is so simple that (busier and more detailed) photos would confuse things.

Technical drawings (because they include scale and more clearly depict ‘exploded’ components) are usually better than photos for high-level use by technicians and engineers.

Both:

Name each image file (and folder) sensibly and number them in the right order, so you can easily find what you need, put images in the right place and switch them in the future.

Back up your image storage (even if in a cloud), so you can’t lose them.

Ensure all image files are in editable formats and that you hold copyright and that none are locked or copy-protected.

Edit images so they’re correctly balanced, framed and sized for better presentation, printing and electronic file sizes.

If all images in a series are equally important, present them in the same dimensions. Readers might think one element of a SOP is more or less crucial than another if images are different sizes.

9. Complete final version and design. Retest.

You’re nearly there!

Complete a final draft of your standard operating procedure, using these steps:

Ask qualified colleagues to review final drafts.

Edit based on their feedback, where appropriate.

Place into the chosen format.

Complete text and graphics.

Check that graphics support your text (and vice-versa).

Review. Double-check final text, grammar, spelling, graphics, design and format.

Don’t forget to create/ make available any external resources your SOPs refer out to.

Sanity check and retest (as described in Step 3 of this article). Amend if necessary.

10. Publish and add to manual (and other resources).

Once your standard operating procedure is complete (previous 9 steps), you must communicate it to your team – and ensure they follow it.

First, publish the SOP within your Operations Manual (and or franchisee operations manual, if franchising).

Your manual must collate all operating procedures and stand as the definitive and unequivocal reference-work for your business. Don’t leave anything out and ensure it is kept up to date.

Your operations manual might be published online using a secure ‘wiki’ or app, as a secure electronic file on your intranet (e.g. locked PDF) or in print.

NB: Don’t assume print is dead. A neatly formatted and printed manual, section, booklet or single SOP can still be easier to read, understand, refer to and enforce (because it’s all there, in the hand) than basic online versions where the reader must search individual topics, scroll pages, view graphics separately and chase fragmented links (making it unlikely they’ll see all the content you want them to).

Then, create integrated tools to communicate your SOP to staff.

Most staff, unless they are in management, are unlikely to read all (or even part) of your operations manual. It is better to think of your manual as the place where you collect definitive and unequivocal versions of standard operating procedures (SOPs), before you turn them into other tools your team will follow and use.

(Don’t get us wrong, it is still imperative that you hold a definitive manual and make it available to team leaders. When enforcing standards, you can’t ‘throw the book at them’ unless you’ve got a book to throw!).

Tools that communicate SOPs well to staff can include:

Formal training (e.g. programmes, workshops, skills development, induction and CPD etc.).

Training bursts (e.g. a five-minute reminder of a SOP or topic given in a briefing).

Training videos (e.g. online videos detailing a single SOP).

Operational booklets by function (i.e. a booklet containing all SOPs, reference and instruction for each job title).

Quick reference cards (i.e. a single SOP on a laminated card at a workstation).

Posters (i.e. a single SOP detailed with graphics, printed large and hung in a section).

Apps. and online reference.

Tests (in training or online) and certification.

Software (i.e. where software prevents a user moving on to the next step without properly completing the current step – and describes what’s needed).

(And properly trained managers who mentor their teams, reinforce your SOPs and enforce standards).

Next steps:

Once your standard operating procedures are complete, they are published and you’ve created tools to communicate them to your team, consider the following next steps:

Create and implement a rollout plan. If you’ve created new SOPs or significantly updated old ones, you need to plan their rollout. Consider when they will come into force, what you need to do to ease the transition from old to new and if you’ve provisioned all the resources they need (e.g. technology, machinery, software, supplies, PPE, external resources, training etc.).

Inform staff that SOPs are changing. Let your team know that new operating procedures are coming, when they start, how they will be trained, the resources that support them, how they will be enforced, etc.

Hold launch events and training. Rollout a programme of events, seminars, training, briefings, memos etc. (as appropriate – in proportion to the magnitude of change) to introduce the new procedures to staff. Explain the benefits, reinforce that you are a progressive organisation and get your team ‘on side’. Don’t expect to get the most from new SOPs just by releasing them without ceremony or explanation in a vacuum.

Then review and update your operations manual and operating procedures regularly (at least annually) to ensure EVERYTHING in them remains accurate. If any element of a SOP becomes defunct, it will undermine the veracity of that procedure and the faith your team holds in your entire manual.

Or keep things simple, let us do it all for you!

Simply ask us to create and update your standard operating procedures, operations manuals (and franchise manuals and user manuals), resources and training for you in simple and affordable ways.

Get in touch with us today, for a friendly chat about your needs – with no obligation.